The Journey of Solar Panels: From Creation to Installation

As the world gradually embraces renewable energy, solar panels have emerged as a quintessential solution for sustainable electricity generation. The transformation of sunlight into usable energy is an intricate process which begins long before the panels are mounted on rooftops or solar farms. This article delves deeply into the journey of solar panels—from their conception and manufacturing to their installation and integration into energy systems.

The Origins of Solar Technology

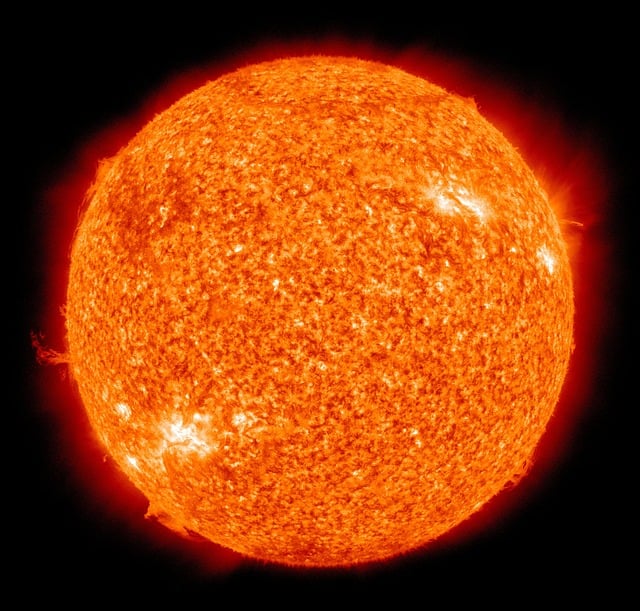

The idea of harnessing solar energy is not new; it dates back to the 19th century. The photovoltaic effect, which is the principle behind solar energy conversion, was discovered by French physicist Edmond Becquerel in 1839. He observed that certain materials produced small amounts of electric current when exposed to sunlight. Despite this groundbreaking discovery, the real commercialization of solar technology didn’t take off until the mid-20th century.

The Manufacturing Process

The process of making solar panels can be broken down into several key stages, each requiring significant technology, resources, and expertise.

Raw Materials

Modern solar panels primarily use silicon as the main raw material. Silicon is abundant and a key component in semiconductor technology. The basic types of silicon used are:

- Monocrystalline Silicon: Made from a single crystal structure, these panels are known for their high efficiency and long lifespan.

- Polycrystalline Silicon: Produced from multiple silicon crystals, they are typically less expensive but also slightly less efficient.

- Thin-Film Technologies: These use various materials such as cadmium telluride or amorphous silicon and are generally lighter and more flexible, though usually less efficient than crystalline panels.

Slicing and Doping

Once silicon is sourced, the next step involves slicing the purified silicon into thin wafers. This is a meticulous process that requires precision and often the use of diamond wire saws. Following this, “doping” occurs, where small amounts of other elements such as phosphorus or boron are added to create p-type and n-type semiconductors. This doping process is crucial, as it enables the creation of an electric field necessary for the photovoltaic effect.

Cell Assembly

The thin wafers are then treated to form solar cells. Each cell is generally around 15% to 22% efficient. They are interconnected to improve voltage output. Various protective layers, such as anti-reflective coatings, are added to enhance efficiency further. Each solar cell plays its part in absorbing sunlight and converting it into direct current (DC) electricity.

Module Production

Once individual cells are formed, they are assembled into solar panels, commonly referred to as solar modules. This assembly involves encasing the cells between layers of glass and a backing material to provide durability and water resistance. During this stage, intricate wiring and junction boxes are incorporated. Each panel is then tested for performance, quality, and safety standards before proceeding to packaging.

The Role of Quality Control

Quality control is an essential aspect of solar panel manufacturing. Manufacturers conduct various tests to ensure that panels meet international standards, such as the IEC (International Electrotechnical Commission) standards. These tests typically include:

- Performance testing under different conditions.

- Durability tests for weather, hail, and heat resistance.

- Electroluminescence testing to detect micro-cracks or defects in the cells.

Quality assurance is vital not only for the longevity of the panels but also for consumer safety and satisfaction.

Transport and Distribution

After production, solar panels undergo careful packaging for transportation. The journey from the factory to the installation site may involve various logistical considerations. Thus, shipping methods may vary from container ships to regional distributors, and careful handling is needed to prevent damage during transit.

The Installation Process

Once the solar panels arrive at their destination, the installation phase begins. This stage involves a plethora of steps, usually carried out by certified solar installers.

Site Assessment

Before installation, a comprehensive site assessment is conducted. Evaluating roof orientation, shading from trees or nearby buildings, and the structural integrity of the roof are pivotal. This assessment helps determine the optimal placement and configuration of solar panels for maximum efficiency.

Permitting and Paperwork

In many regions, obtaining the necessary permits and complying with local regulations is essential. This can involve paperwork regarding zoning, electrical permits, and, in some cases, environmental assessments. Understanding local laws and regulations is crucial for a successful installation process.

Installation of Mounting Systems

The next step involves the installation of the mounting system. Mounts can either be rooftop-mounted or ground-mounted, depending on the project requirements and conditions. The mounting system provides a secure base for the panels and can require special tools for installation.

Panel Installation

With the mounting base in place, solar panels are carefully installed. Professional installers connect panels in a manner that optimizes performance while considering electrical wiring and connections. Depending on the system design, inverters—devices that convert DC to AC electricity—are also integrated during this stage.

Electrical Connection and Testing

Once all panels are installed, and connections are made, the system undergoes a series of tests. This step ensures that the solar energy system is functioning correctly and seamlessly integrates with the building’s electrical system. Safety and performance checks are conducted to confirm that the system meets legal and industry standards.

Grid Connection and Monitoring

After successfully passing tests, the final step involves connecting the solar energy system to the utility grid. This process may vary by location and usually requires final inspection by local authorities or utility companies. Once connected, many systems come equipped with monitoring equipment, allowing users to track energy production, consumption, and system performance through a user-friendly interface.

The Future of Solar Technology

The journey of solar panels from creation to installation showcases the complexity and dedication involved in harnessing renewable energy. As technology advances, the solar industry is continuously evolving. Innovations such as bifacial panels, building-integrated photovoltaics (BIPV), and energy storage solutions like lithium-ion batteries are paving the way for a more sustainable and efficient energy future.

Moreover, ongoing research into increasing the efficiency of solar cells and reducing manufacturing costs will ensure that solar energy remains accessible and attractive. The solar revolution is not just a trend; it represents a fundamental shift towards cleaner, greener energy sources that promise a brighter future for generations to come.

Conclusion

The journey of solar panels embodies both technological advancement and environmental concern. As solar energy becomes a more integral part of our energy landscape, understanding how these panels are created and installed can help individuals and businesses make informed decisions about adopting solar technology. The path from raw materials to rooftop installation is but a step in a larger movement toward sustainable energy solutions that hold the potential to reshape our world.